Email:sales@bundor.com | Tel: +86 150 0225 9955 | Wechat: Bundor_marketing | Skype: +86 150 0225 9955

Email:sales@bundor.com | Tel: +86 150 0225 9955 | Wechat: Bundor_marketing | Skype: +86 150 0225 9955

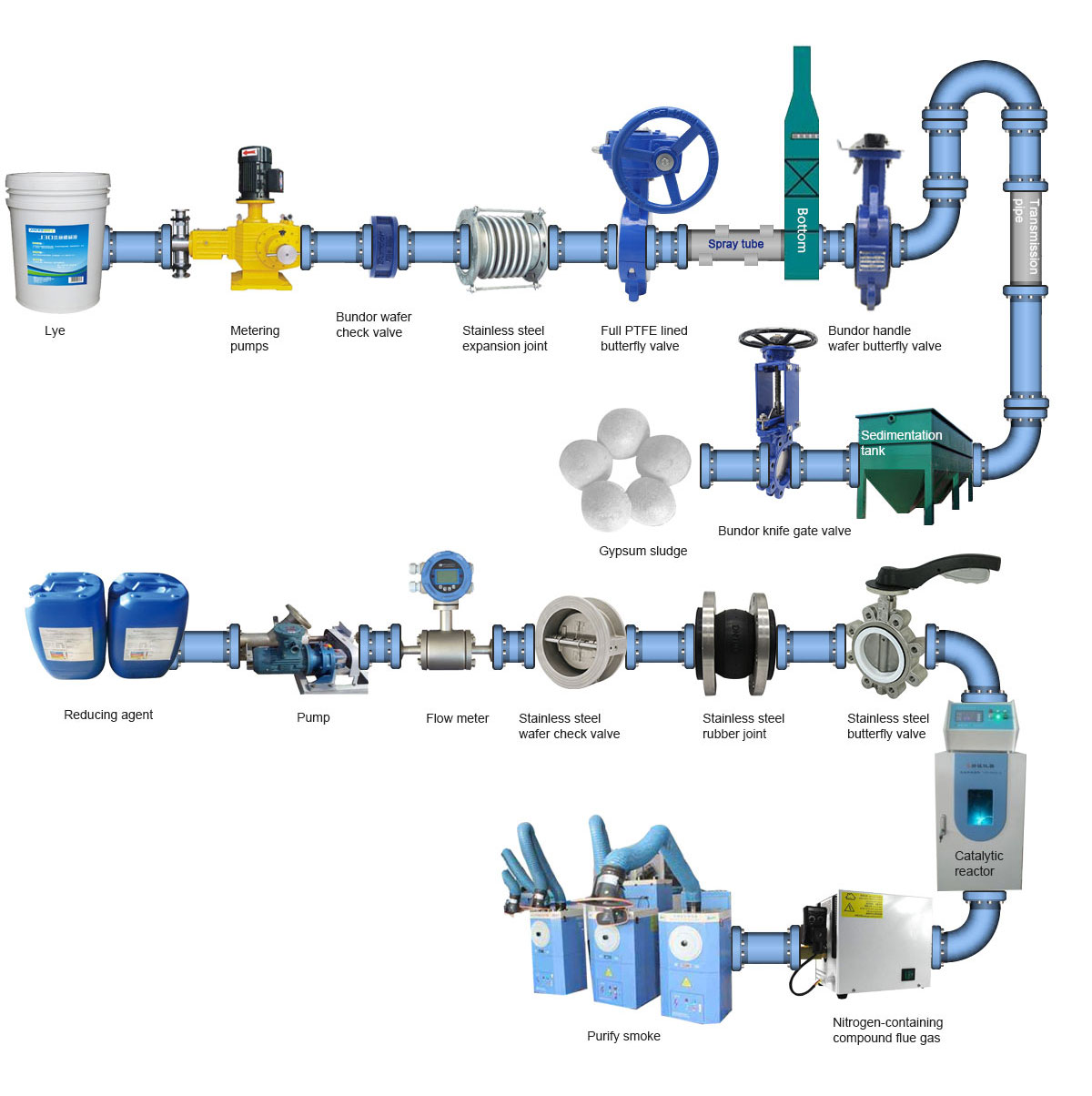

Bundor valve provide you with a complete set of safe and reliable flue gas desulfurization and denitrification valve solutions

Bundor valve is committed to provide the high quality valve products and considerate services for the society. Bundor valve has an irreplaceable advantages, was founded in 1994, more than 20 years of research and development production experience, has 102 patent certificate, 5000㎡ production workshop, and equipped with a valve industry leading intelligent testing center, to ensure the qualified rate of valve quality. At the same time to solemnly promise to customers, Bundor valve two years warranty. Because the product itself quality question, the unconditional compensation.

| No. | Name | Pressure | Configuration | Unit |

|---|---|---|---|---|

| 1 | Handle wafer butterfly valve | PN16 | DI body,DI disc,EPDM seat | set |

| 2 | Wafer check valve | PN16 | DI body,DI disc,EPDM seat | set |

| 3 | PTFE/Teflon Seat Buttefly Valve | PN16 | WCB body,PTFE straine | set |

| 4 | Stainiess steel wafer check valve | PN16 | 304 body,304 disc,EPDM seat | set |

| 5 | Stainiess steel butterfly Valve | PN16 | 304 body,304+PTFE disc,PTFE seat | set |

| 6 | Stainiess stee rubber joint | PN16 | 304 Flange,EPDM seat | set |

| 7 | Knife gate valve | PN16 | WCB body,304 disc,EPDM seat | set |

Overview of pneumatic triple eccentric butterfly valve: Pneumatic triple eccentric butterfly valve consists of pneumatic actuator and triple...