Working principle of Dual plate check valve

Posted by Bundor valve

In this article, Bundor Valve will introduce the working principle of dual plate check valve to you.

Overview of dual plate check valve:

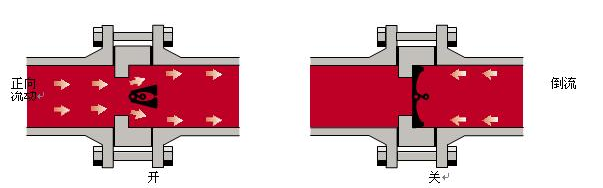

The dual plate check valve is a kind of check valve with rotary action, but it is a double disc and is closed under the action of a spring. The bottom-up fluid pushes the valve disc open. The dual plate check valve has a simple structure and is installed between two flanges. It is mainly used in various engineering pipelines and other valves to prevent the backflow of the medium.

The working principle of dual plate check valve:

The double disc structure adopts two spring-loaded valve discs, which are suspended on the vertical shaft in the center. When the fluid begins to flow, the disc opens under the combined force acting on the center of the sealing surface.

The point of action of the reacting spring support force is located outside the center of the disc face, so that the base of the disc opens first. This avoids the friction of the sealing surfaces of the old conventional valve when the disc is opened, and eliminates the wear of the components.

When the flow rate slows down, the torsion spring automatically reacts, so that the valve disc closes and moves closer to the valve seat, reducing the travel distance and time for closing. When the fluid flows backwards, the valve disc gradually approaches the valve body and valve seat, and the dynamic response of the valve is greatly accelerated, reducing the cumulative effect of the water hammer phenomenon, thereby achieving non-impact performance. When closing, the action point of the spring force causes the top of the valve disc to close first, preventing the root of the valve disc from biting and rubbing, so that the valve can maintain the sealing integrity for a longer time.

Overview of dual plate check valve:

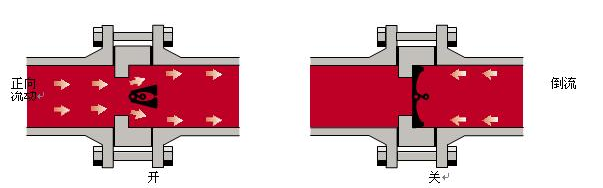

The dual plate check valve is a kind of check valve with rotary action, but it is a double disc and is closed under the action of a spring. The bottom-up fluid pushes the valve disc open. The dual plate check valve has a simple structure and is installed between two flanges. It is mainly used in various engineering pipelines and other valves to prevent the backflow of the medium.

The working principle of dual plate check valve:

The double disc structure adopts two spring-loaded valve discs, which are suspended on the vertical shaft in the center. When the fluid begins to flow, the disc opens under the combined force acting on the center of the sealing surface.

The point of action of the reacting spring support force is located outside the center of the disc face, so that the base of the disc opens first. This avoids the friction of the sealing surfaces of the old conventional valve when the disc is opened, and eliminates the wear of the components.

When the flow rate slows down, the torsion spring automatically reacts, so that the valve disc closes and moves closer to the valve seat, reducing the travel distance and time for closing. When the fluid flows backwards, the valve disc gradually approaches the valve body and valve seat, and the dynamic response of the valve is greatly accelerated, reducing the cumulative effect of the water hammer phenomenon, thereby achieving non-impact performance. When closing, the action point of the spring force causes the top of the valve disc to close first, preventing the root of the valve disc from biting and rubbing, so that the valve can maintain the sealing integrity for a longer time.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor